Sludge Digester in Wastewater Treatment

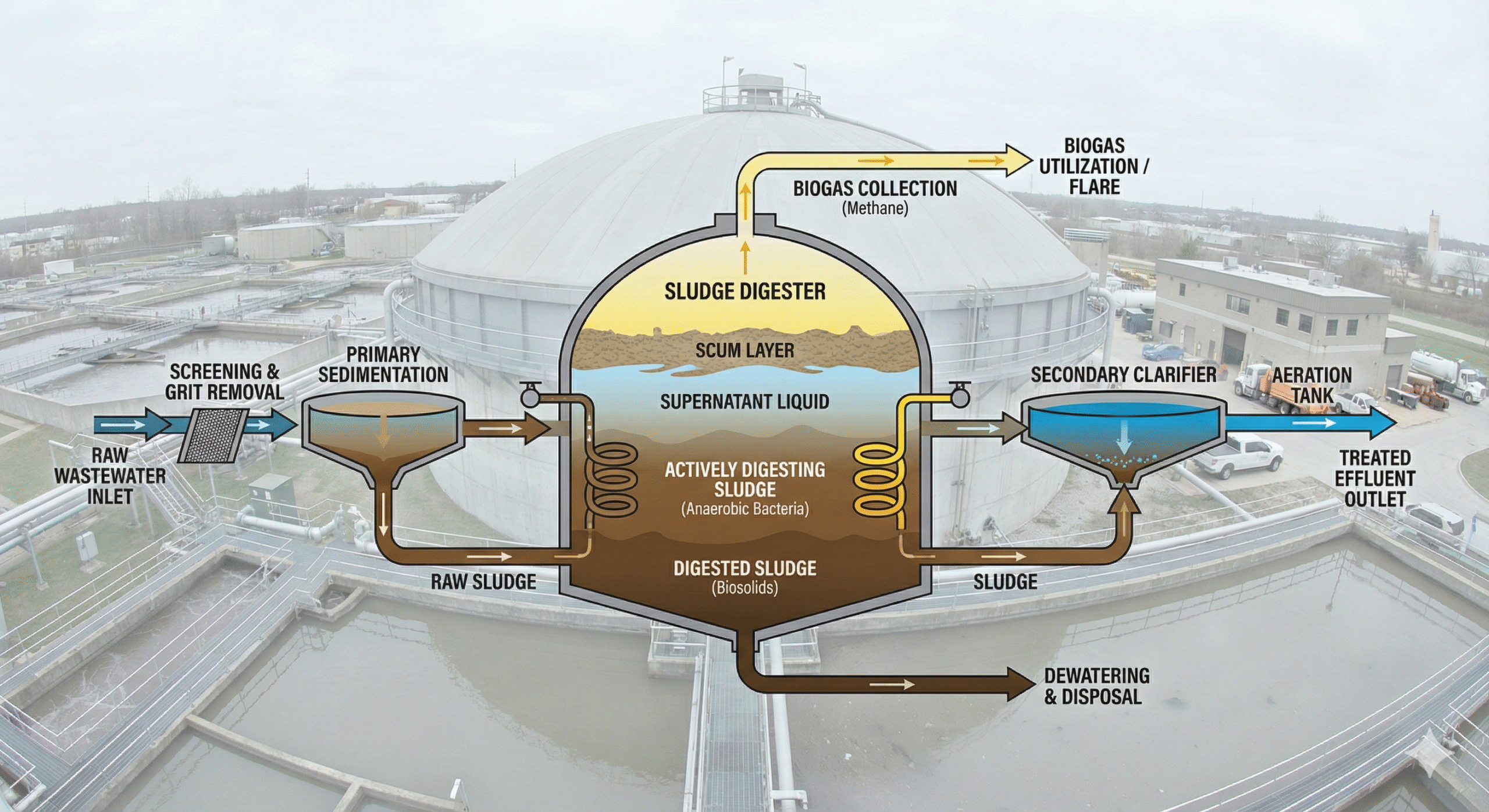

A sludge digester is a critical component in wastewater treatment plants (WWTPs) designed to stabilize the solids (sludge) removed from wastewater. Its primary goals are to reduce the volume of the sludge, destroy harmful pathogens, and often generate renewable energy in the form of biogas.

The most common type used in large-scale treatment plants is the Anaerobic Digester (operating without oxygen). Below is the detailed process.

1. Overview of the Process

The sludge digestion process mimics a “biological stomach.” Raw sludge (primary sludge from settling tanks and secondary sludge from biological treatment) is pumped into a sealed, air-tight tank. Inside, specific groups of bacteria break down the organic matter in a sequential biological chain reaction.

2. The Four Stages of Anaerobic Digestion

The biological breakdown occurs in four distinct stages. If any stage fails, the digester can become “sour” (acidic) and stop working.

Stage 1: Hydrolysis

What happens: Complex organic polymers (fats, proteins, and carbohydrates) are too large for bacteria to “eat.” In this stage, fermentative bacteria secrete enzymes to break these down into soluble monomers (simple sugars, amino acids, and fatty acids).

Result: Solid organic matter turns into liquid dissolved organic matter.

Stage 2: Acidogenesis (Acid Fermentation)

What happens: Acidogenic bacteria absorb the dissolved food from Stage 1. They ferment these simple sugars and amino acids.

Result: Creation of Volatile Fatty Acids (VFAs) like propionic and butyric acid, along with ammonia, carbon dioxide ($CO_2$), and hydrogen sulfide ($H_2S$). The pH of the sludge drops (becomes acidic) during this phase.

Stage 3: Acetogenesis

What happens: Acetogenic bacteria convert the volatile fatty acids created in Stage 2 into acetic acid, hydrogen, and carbon dioxide.

Result: Formation of the direct precursors for methane gas (Acetate and Hydrogen).

Stage 4: Methanogenesis (Methane Production)

What happens: Methanogens (a special type of archaea) act on the acetic acid and hydrogen. This is the most sensitive stage; these microbes are strictly anaerobic and easily killed by oxygen or low pH.

Result: Waste is converted into Methane ($CH_4$) and Carbon Dioxide ($CO_2$). The pH stabilizes back to neutral (around 7.0).

3. Operational Conditions

For the bacteria to survive, the digester must maintain a specific environment, much like a human body.

| Parameter | Mesophilic Digestion | Thermophilic Digestion |

| Temperature | 30°C – 38°C (Most common) | 50°C – 60°C |

| Pros | Stable, bacteria are robust, requires less heating energy. | Faster digestion, kills more pathogens (Class A biosolids). |

| Cons | Slower processing time (20–30 days). | Sensitive to temperature changes; requires more heating energy. |

Retention Time: The sludge typically stays in the digester for 15 to 30 days to ensure full breakdown.

Mixing: Mechanical stirrers or gas recirculation systems mix the sludge continuously to prevent a crust (scum) from forming on top and to ensure bacteria touch the food.

4. Digester Tank Configurations

Standard Rate (Single Stage): Digestion, sludge thickening, and supernatant formation all happen in one tank. This is slower and less efficient.

High Rate (Two Stage):

Tank 1: Heated and mixed. This is where the active biological digestion happens rapidly.

Tank 2: Unheated and unmixed. This acts as a settling tank where the digested sludge separates from the liquid (supernatant) and gas is collected.

5. Final Outputs

Biogas: A mixture of roughly 60-70% Methane and 30-40% $CO_2$. This is captured and often burned in Combined Heat and Power (CHP) engines to generate electricity for the plant.

Digestate (Biosolids): The remaining solid material. It is nutrient-rich (Nitrogen and Phosphorus), pathogen-free, and odorless. It is dewatered (dried) and used as fertilizer or soil conditioner.

Supernatant: The liquid separated from the sludge. It is high in ammonia and is usually sent back to the head of the treatment plant for re-treatment.

All Categories

Recent Posts

Hello world!

Effluent Treatment Plant

Sludge Digester in Wastewater Treatment