Effluent Treatment Plant

An effluent treatment plant (ETP) cleans wastewater through a sequence of physical, chemical, and biological steps to remove solids, oils, nutrients, and dissolved contaminants so the treated water is safe to discharge or reuse. Below is an end-to-end walkthrough of the process, what each stage removes, and how plants are operated and monitored.

What ETPs Treat

-

Suspended solids such as grit, silt, and fibers.

-

Floatables and oils including free oil and emulsified oil.

-

Dissolved organics measured as BOD and COD.

-

Nutrients including nitrogen and phosphorus.

-

Toxic or recalcitrant compounds like dyes, phenols, heavy metals, and surfactants.

-

Microorganisms (pathogens).

Process Flow Overview

-

Inlet works: screening, grit removal, oil-water separation.

-

Flow equalization and pH/alkalinity control.

-

Chemical pretreatment: coagulation, flocculation, dissolved air flotation or primary clarification.

-

Biological treatment: activated sludge/MBBR/SBR/MBR for BOD/COD and nutrient removal.

-

Tertiary polishing: filtration, activated carbon, advanced oxidation, nutrient polishing.

-

Disinfection: chlorination, sodium hypochlorite, or UV.

-

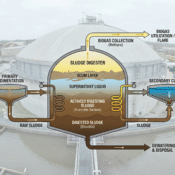

Sludge line: thickening, stabilization, dewatering, disposal or reuse.

Preliminary and Pretreatment

-

Screening: removes rags, plastics, and large debris to protect downstream equipment.

-

Grit removal: removes sand and heavy inorganics that cause abrasion and sedimentation.

-

Oil-water separation: plate separators or API separators remove free oil and grease.

-

Equalization: balances fluctuating flows and loads; provides buffering against shock loads.

-

pH and alkalinity control: acid/alkali dosing to bring pH typically to 6.5–8.5 for optimal treatment.

-

Coagulation–flocculation: metal salts or polymers agglomerate colloids and emulsions.

-

Primary clarification or DAF: separates formed flocs; DAF is preferred for oily or emulsified streams.

Primary Treatment

-

Settling of heavier solids to produce primary sludge.

-

Skimming of floatables and residual oils.

-

Reduces suspended solids and some BOD, improving downstream biological performance.

Secondary (Biological) Treatment Options

-

Conventional activated sludge: aeration tanks with return activated sludge; targets high BOD/COD removal.

-

MBBR: biofilm carriers increase biomass and resilience in variable industrial effluents.

-

SBR: fill–react–settle cycles in a single basin; compact for small plants.

-

MBR: membranes replace clarifiers for very low turbidity and bacteria; compact footprint and high-quality effluent.

-

Key controls: dissolved oxygen, sludge age, F/M ratio, nutrient balance BOD:N:P≈100:5:1BOD:N:P≈100:5:1.

Typical removals in well-run systems:

-

BOD: 85–98%

-

COD: 60–90% (higher with pre-oxidation or MBR)

-

TSS: >95%

Nutrient Removal

-

Nitrogen: nitrification–denitrification via aerobic and anoxic zones; supplemental carbon may be needed.

-

Phosphorus: chemical precipitation with alum/Fe salts or enhanced biological phosphorus removal.

-

Targets depend on discharge limits; TN and TP polishing may be added when receiving waters are sensitive.

Tertiary and Advanced Treatment

-

Filtration: sand, dual-media, or membrane filtration for fine solids.

-

Activated carbon: removes color, odors, and residual organics.

-

Advanced oxidation: ozone, UV/H2O2, or Fenton to degrade refractory compounds.

-

Desalination/reuse: softening or RO where low TDS is required; manage RO reject responsibly.

-

Disinfection: chlorine, hypochlorite, or UV to meet microbial standards.

Sludge Treatment and Disposal

-

Thickening: gravity or DAF thickening to reduce volume.

-

Stabilization: aerobic or anaerobic digestion to reduce odors and pathogens.

-

Dewatering: centrifuge, belt press, plate-and-frame press to produce cake.

-

End use: composting or land application (if compliant), co-processing, incineration, or secure landfill.

-

Centrate/filtrate returns to the headworks and must be accounted for in loading.

Monitoring and Control

-

Online instruments: pH, DO, ORP, turbidity/solids, flow, temperature, and sometimes ammonia or nitrate.

-

Lab testing: BOD, COD, TSS, oils and grease, nutrients, metals, and microbiology.

-

Automation: PLC/SCADA adjusts aeration, recycle rates, chemical dosing based on influent variation.

-

Compliance: routine sampling and reporting to demonstrate permit adherence.

Typical Performance Targets

-

TSS < 30 mg/L

-

BOD < 20 mg/L

-

COD < 100 mg/L

-

Oils and grease < 10 mg/L

-

Ammonia-N < 5 mg/L (where required)

-

TN 10–20 mg/L and TP 1–2 mg/L for sensitive waters

Actual limits depend on local regulations and receiving water sensitivity.

Common Small-Plant Trains (up to ~100 KLD)

Domestic/sewage (STP-like):

-

Screen and grit removal

-

Equalization with fine screens

-

MBBR or SBR biological process

-

Secondary clarification (if MBBR) or integrated settling (SBR)

-

Pressure sand filter + activated carbon filter

-

UV or chlorination for disinfection

-

Sludge thickening and dewatering

Industrial with oils/emulsions:

-

Coarse screen, grit, oil-water separator

-

Equalization with pH control

-

Coagulation–flocculation + DAF

-

MBBR or MBR for secondary treatment

-

Tertiary filtration and activated carbon

-

AOP if refractory COD/color persists

-

Disinfection and reuse/discharge

-

Sludge handling as above

Color/recalcitrant organics (e.g., dyes, pharma):

-

Equalization and pH control

-

Advanced oxidation pre- or post-biological

-

High-rate MBR for deep polishing

-

Activated carbon and potential RO for reuse

-

Robust sludge management and concentrate handling

STP vs ETP (at a glance)

| Aspect | STP (Sewage) | ETP (Industrial Effluent) |

|---|---|---|

| Typical influent | Biodegradable organics, nutrients | Variable; oils, metals, surfactants, color, toxics |

| Key pretreatment | Screening, grit | Screening, grit, oil separation, pH, coag/floc, DAF |

| Biological process | Activated sludge, MBBR, SBR | Activated sludge, MBBR, SBR, MBR with higher resilience |

| Polishing | Filtration, disinfection | Filtration, carbon, AOP, nutrient removal, disinfection |

| Challenges | Flow variation, nutrient control | Toxic shocks, emulsions, recalcitrant COD, metals |

| Reuse needs | Low TDS applications | Often RO/softening based on product needs |

Practical Operating Tips

-

Maintain equalization to dampen shock loads and keep pH within treatment windows.

-

Control biomass health: track DO, sludge age, SVI, and F/M; avoid over- or under-aeration.

-

Dose chemicals based on jar tests; adjust coagulant/polymer to influent changes.

-

Ensure nutrient balance for biological treatment; supplement N/P when treating weak streams.

-

Keep a preventive maintenance and calibration schedule for instruments and blowers.

-

Plan for safe chemical storage and sludge disposal; verify regulatory compliance before land application.

Example: 100 KLD ETP Equipment List (typical)

-

Bar screen and vortex grit chamber

-

Equalization tank with mixers and pH control

-

Coagulation–flocculation tank with dosing skids

-

DAF unit or primary clarifier

-

MBBR or SBR basin with blowers and diffusers

-

Secondary clarifier (if MBBR) or integral settling (SBR)

-

Pressure sand filter and activated carbon filter

-

UV or chlorination system

-

Sludge thickener and centrifuge/belt press

-

PLC/SCADA with online pH, DO, flow, and turbidity meters

If you share your influent characteristics (flow, pH, BOD, COD, TSS, oils, color, nutrients, metals) and reuse/discharge targets, I can propose an optimized process train and sizing assumptions for your capacity

All Categories

Recent Posts

Hello world!

Effluent Treatment Plant

Sludge Digester in Wastewater Treatment